How Operation Visibility Enhanced Production for Nepal's Luxury Knitwear Brand

The Company

Tricot Nepal is a leading cashmere manufacturer under Nepal's Golyan Group. Established in 2001, it combines decades of textile expertise with modern innovation. The company seamlessly blends traditional craftsmanship with cutting-edge technology to deliver world-class cashmere products to global fashion houses.

Renowned for its uncompromising quality standards, Tricot has cultivated enduring partnerships with international luxury brands. The company's commitment to ethical manufacturing and sustainable practices positions it as a trusted leader in the flat-knitwear supply chain.

Tricot operates with 80 advanced STOLL knitting machines (3gg–16gg) and Rezacci Spa finishing technology, enabling a production capacity of 30,000 pieces per month. Each garment undergoes stringent quality checks to ensure it meets the highest standards before reaching customers.

IMPACTS BROUGHT BY KNITONE SOLUTIONS

CHALLENGES

- Traditional (paper-based) methods caused inefficiencies despite premium product quality.

- Excel-based sales and finances delayed decisions and carried a high risk of errors.

- Poor visibility, error-prone yarn tracking, and slow order updates across departments.

- No clear data on machine utilization, efficiency, and downtime.

- People's dependencies slowed communication and led to inaccurate updates for clients.

- Lack of stage-wise monitoring for product inconsistencies.

- The entire production planning process was reactive rather than proactive.

- Scattered sales data caused costly delays.

WHY DID TRICOT NEPAL CHOOSE KNITONE?

Tricot Nepal is a subsidiary of Golyan Group, a diversified business conglomerate active in multiple sectors including agriculture, financial services, real estate, hospitality, renewable energy and manufacturing. The group adopted SAP to strengthen financial management across all of its business units.

KnitOne is a tailored ERP for knitwear manufacturers, giving them control from yarn to growth, all in one view. It was developed by AstraSoftech to directly address the gaps in traditional ERPs. With this ERP solution, knitwear manufacturers can have granular operational control and deep financial insights that fuel growth. Moreover, KnitOne is best for small to mid-sized knitwear manufacturers, vertical fashion brands, and designers or startups within the knitwear sector.

However, the implementation of SAP surfaced several practical concerns. Capturing real-time data from Tricot’s factory operations proved difficult within the system. In addition, the user interface (UI/UX) was primitive, which made frequent use challenging. Given these constraints, deploying SAP across Tricot’s factory operations appeared increasingly impractical. This led Tricot to explore alternatives that offered a closer fit to knitwear manufacturing processes. Their search ultimately brought them to KnitOne.

SOLUTIONS PROVIDED BY KNITONE

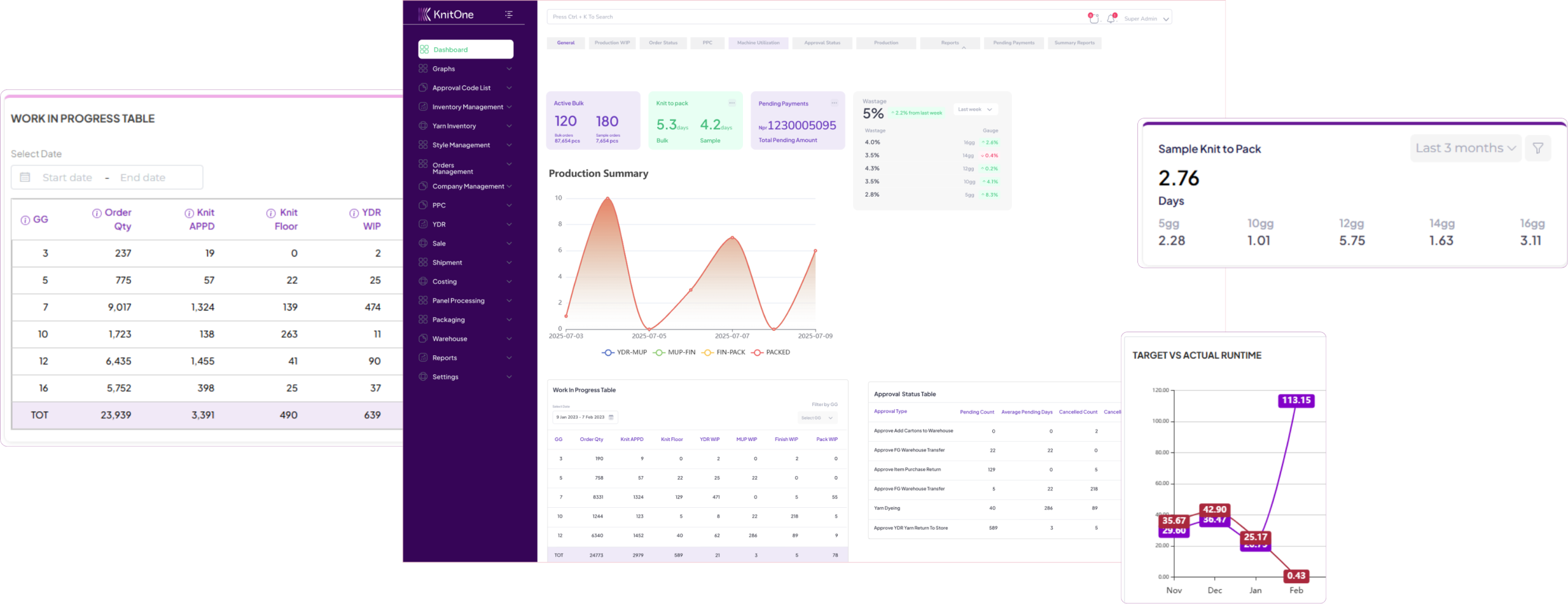

Automated Dashboards Replacing Excel Formulas

Accurate Sampling Cost Calculations Usable for Bulk Production

Managed yarn-related Pre-Production Actions

Efficient Production Planning to Optimize Factory Workflow

Detailed Analysis of Machine Usage in Factory

Dynamic Quality Check (QC) of Items

SFG (Semi-Finished Goods) Movement Tracking

Organized Order-by-Order Sales Insights

KnitOne’s Wastage Tracking –

The Hidden Key to Profitability For a luxury brand like Tricot, a 3–5% yarn loss could translate into an annual cost of approximately $150,000. While KnitOne was actively improving the order-toproduction process, it identified this hidden opportunity to reduce waste. Tricot then gained clearer visibility into yarn overbuying and yarn losses during knitting, finishing, and the leftover stages. With these insights, they tightened control, cut waste significantly, and boosted profits. Today, Tricot continues to leverage enhanced visibility, achieving significant cost savings and improved operational efficiency.

KEY TAKEAWAYS

By adopting KnitOne, Tricot Nepal transformed complex costing into precise, rapid calculations. Production planning evolved from reactive guesswork to clear, data-driven scheduling. Enhanced machine performance and early defect detection elevated product quality. Meanwhile, stringent wastage control significantly improved profitability.

Just like Tricot Nepal, you’ve built your knitwear business with vision and grit. Now is the time to make your business run faster, better, and with fewer headaches, without having to change how you do business. All of these are possible with KnitOne-Tailored ERP for Knitwear Manufacturing.